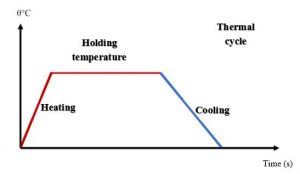

The heat treatment is a succession of operations in which a solid ferrous product is subjected wholly or partially to thermal cycles to obtain a change in its properties and/or structure.

A distinction is made between different heat treatments such as quenching, annealing and tempering. In order to guarantee good mechanical and microstructural properties of a treated material, the choice of temperature and treatment time is a crucial step. Generally, heat treatment is carried out by the conventional method (gas furnace), however, this methodology is still limited in terms of final structure and productivity. In this context, the capacities of La GTM France, as the leader in heat treatment, are occurred. Indeed, La GTM France has introduced induction heat treatment as a new process in order to improve structural homogeneity and mechanical properties on the one hand and to increase productivity on the other hand. This treatment undergoes structural transformations of metals through predetermined heating and cooling cycles in order to modify their mechanical characteristics: hardness, ductility, resilience…

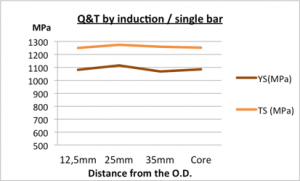

According to the obtained results, the induction heat treatment succeeded in the following criteria:

- Reduce the treatment time thanks to the continuity of the operation (bars to bars)

- Have a homogeneous final structure

- Reduce decarburization

- Reduce product deformation (tubes/ bars)

- Ensure flexibility of parameter settings during processing

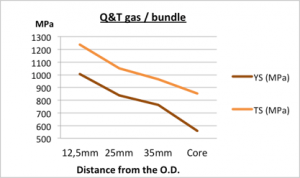

On the other hand, the conventional treatment (gas furnace) always presents the same problems such as :

- Heterogeneity of structure

- Long operating time

La GTM France offers a wide range of induction heat treatment services. The equipment is able of processing a wide range of components of different sizes (from Ø 10 mm up to Ø 250/354 mm for tubes/ bars, respectively), according to the strictest standards, with reliable and reproducible results.

Contact us for any questions or inquiries.